What Is Control Cable: An Incredibly Easy Technique That Works For All

페이지 정보

본문

The jacket is the outermost layer of protection for the cables within your custom cable assembly and can be made from a wide variety of materials. Depending on your needs, we can create your cable jackets to maximize flexibility, increase durability, or perhaps add a layer of moisture protection for your conductors. Depending on the firm, you’ll be qualified to turn out to be a property manager directly via your company. Meridian Cable Company is a cable manufacturing and assembly firm that provides quality services across multiple industries. In this article, we will explore how streaming services are changing the game and revolutionizing the television industry. Government to provide testing services. Inside our Advanced Life Testing Lab we’re able to put cable assemblies through the toughest conditions and tests imaginable to make sure they’re up to the tasks they’re being asked to accomplish. See the maglock wiring diagram below to make sure that you have wired your access control system correctly.

With cutting-edge design and modeling software, we can see how all the components come together virtually before we extrude the first wire. Most consumers see "custom" and think this equates to more expensive. With the rise of online live television and streaming services, viewers now have more control over what they watch and when they watch it. We leverage our different facilities logistically to be able to manufacture and ship cable assemblies and other products to customers the world over. Our company has more than 25 years of experience in serving customers in numerous industries, including medical, industrial control, broadcasting, telecommunications, retail security, and much more. Our inventory of over 5,000 molds means our customers have a wide variety to choose from. A cable assembly can run the gamut from simple applications such as a coax cable transmitting signals from a television to a sound system, what is control cable to incredibly complex bundles of sometimes well over 50 different conductors distributing electricity and signals throughout a system like the cockpit of a fighter jet. Ready to talk over your project specifications with our design team? OEMs will specify the exact requirements for a mass-produced component like a cable assembly for a vehicle and we can help manufacture this to identical predetermined specifications.

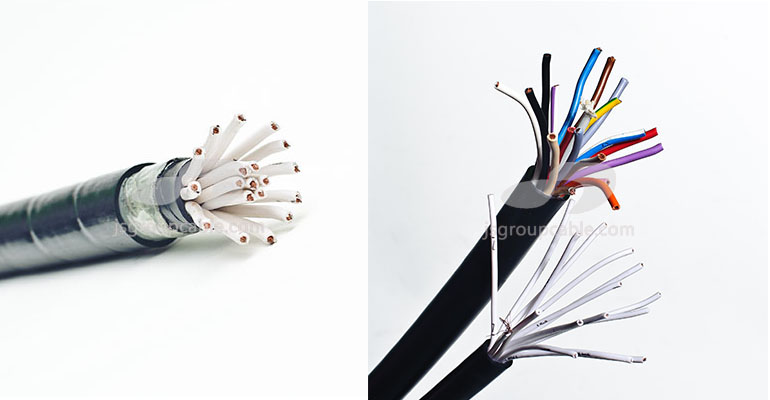

This means we can create a custom solution that’s been tested and retested for continuity, integrity, and functionality. At its simplest, custom cable manufacturing and design will provide your company with a customized solution to meet your most exacting requirements for cable manufacturing and assembly. This helps save time and money during the manufacturing and installation process as the parts will be uniform to the originals. Now that you have built the cable within your custom cable assembly from the wire out, you are ready to start the process of building the entire cable assembly. Custom molding features include enclosure strain relief to protect your cable from bend failure, using a choice of materials. The Xtreme cables, for instance, offer a 4-inch bend radius, while the tightest turn a standard cable can tolerate is 8 inches. It also means that there are many layers of wires within a control cable and you can’t tell the true condition of a cable from a cursory visual inspection while it is installed in the aircraft. They are subject to wear and deterioration and remain in static positions around pulley bends for extended periods of time while the aircraft sits.

At Meridian, every single product that rolls of the line is tested each and every time. At Meridian, our entire philosophy revolves around quality. This fanatical attention to Quality Assurance allows us to deliver consistent products to customers, who know they can count on the cable assembly to perform as designed for years to come. On not unusual Assets, expenses double every eleven years. Therefore, we offer a full, one-year warrantyagainst material defects and workmanship. Actually, our custom designs usually save our clients money in the long run because it helps cut sourcing costs, production time, and reduces chances for defects. We know your custom cable assembly simply has to perform. However, fillers do, in fact, provide several critical support functions to the cable assembly. However, because our design capabilities are so versatile, we can design the perfect set-up for just about any application you can imagine. Meridian Cable has the capabilities to custom design, extrude and manufacture all types of coil cords or coiled cables. If you need custom cable assemblies, does a company you’re considering offer recommendations for materials and construction processes? When it comes to cable assemblies, your cable assembly manufacturer needs to be intimately familiar with your intended application, taking into account all of the variables that can play into longevity and performance.

- 이전글Methods to Make Your Free Poker Look Wonderful In 5 Days 25.05.06

- 다음글Diverse Communities 25.05.06

댓글목록

등록된 댓글이 없습니다.